▲ Comparison of HDPE sheets produced by different processes

1. Classification by production process : the key to determining the physical properties of HDPE sheets The key to physical performance

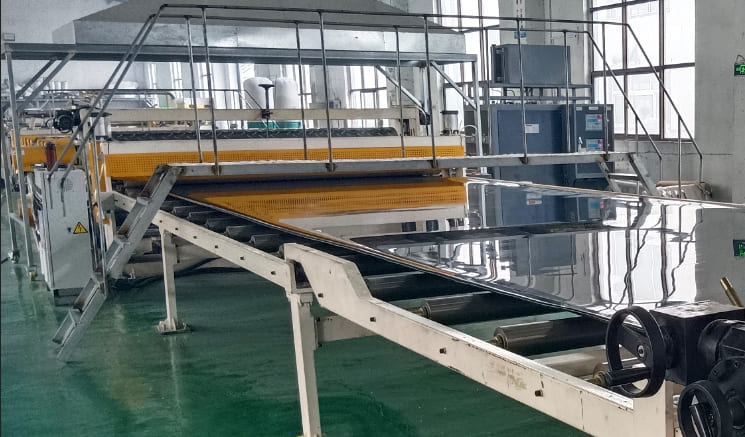

1.1 Extrusion molding HDPE sheet

Using single screw extruder for continuous production, the thickness range is 1-50mm, the width can reach 3 meters, and it has the following characteristics:

- ● Density 0.945-0.965g/cm³ (conforms to ASTM D4976 standard)

- ● Surface finish Ra≤3.2μm

- ● Typical applications: chemical tank lining, food grade operating table

1.2 Compression molded HDPE sheet

Made by hot pressing process, suitable for making special-shaped parts, main parameters:

- ● Operating temperature range -50℃~90℃

- ● Tensile strength ≥28MPa (20% higher than ordinary extruded plates)

- ● Common specifications: 10-100mm thick customized parts

2. Classification by application field : Professional solutions

that match scenario requirements

| Type |

Key indicators |

Application cases |

| Food grade HDPE board |

FDA 21 CFR certified

Heavy metal content < 5ppm |

Dairy processing equipment, beer fermentation tanks |

| Medical HDPE board |

Complies with ISO 10993 biocompatibility test

Surface resistivity 10^6-10^9Ω |

Surgical instrument trays, pharmaceutical packaging |

| Engineering grade HDPE board |

Shore hardness D65-70

Abrasion resistance < 100mm³/km |

Mine chute lining, marine anti-collision strip |

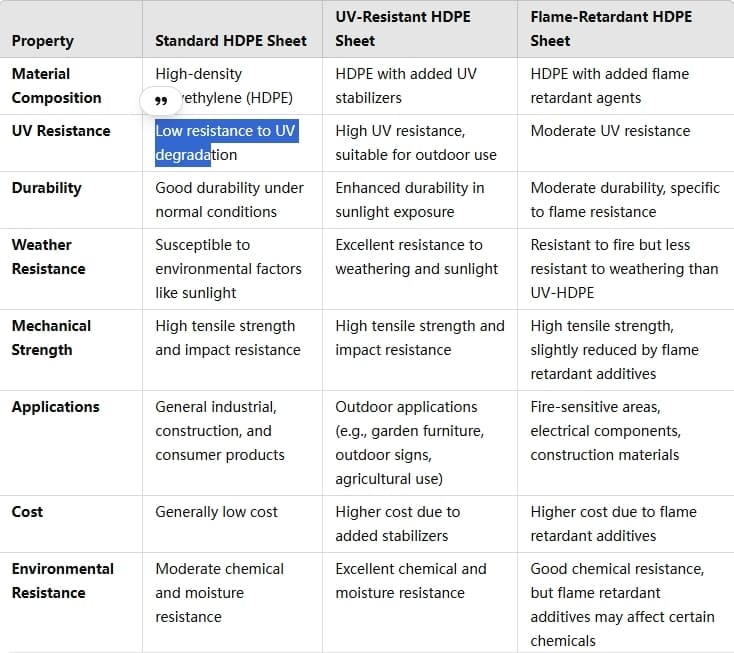

3. Classification by modified additives : HDPE sheet special features

3.1 Anti-ultraviolet type

Adding 2-3% carbon black masterbatch, the outdoor service life can reach more than 10 years (passed QUV 3000 hours test).

3.2 Flame retardant type

Achieves UL94 V-0 rating, oxygen index>28%, suitable for electronic equipment housing and other scenarios.

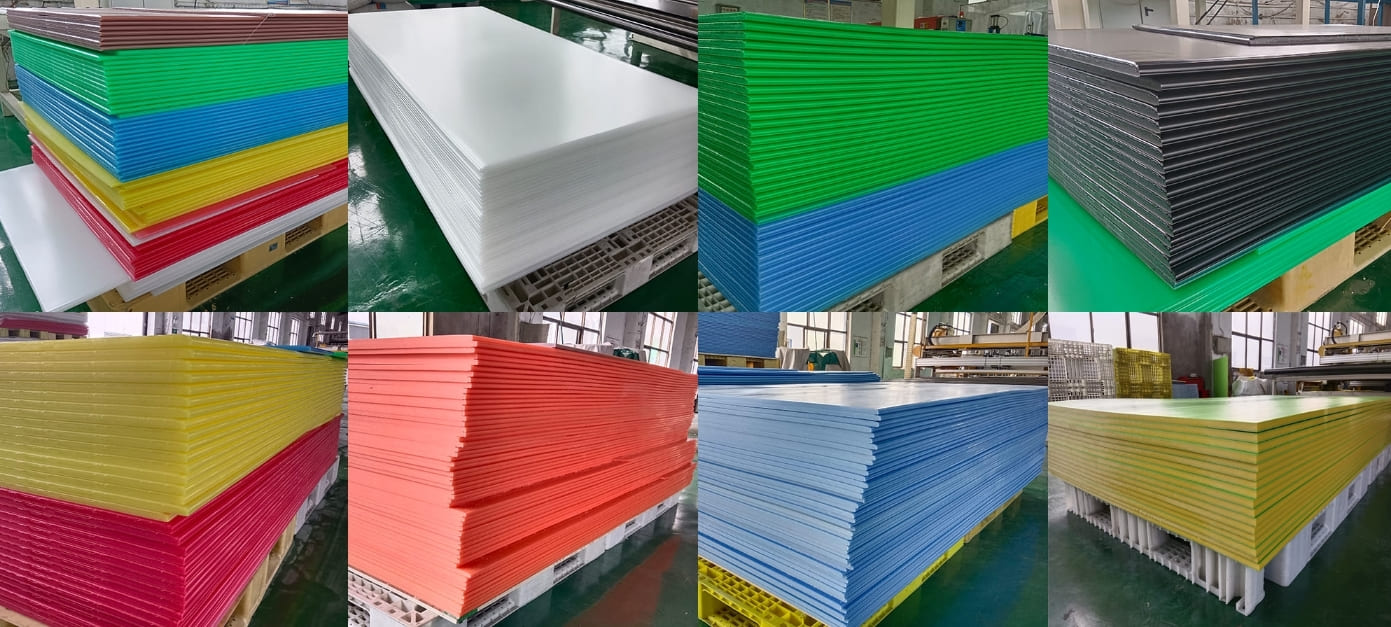

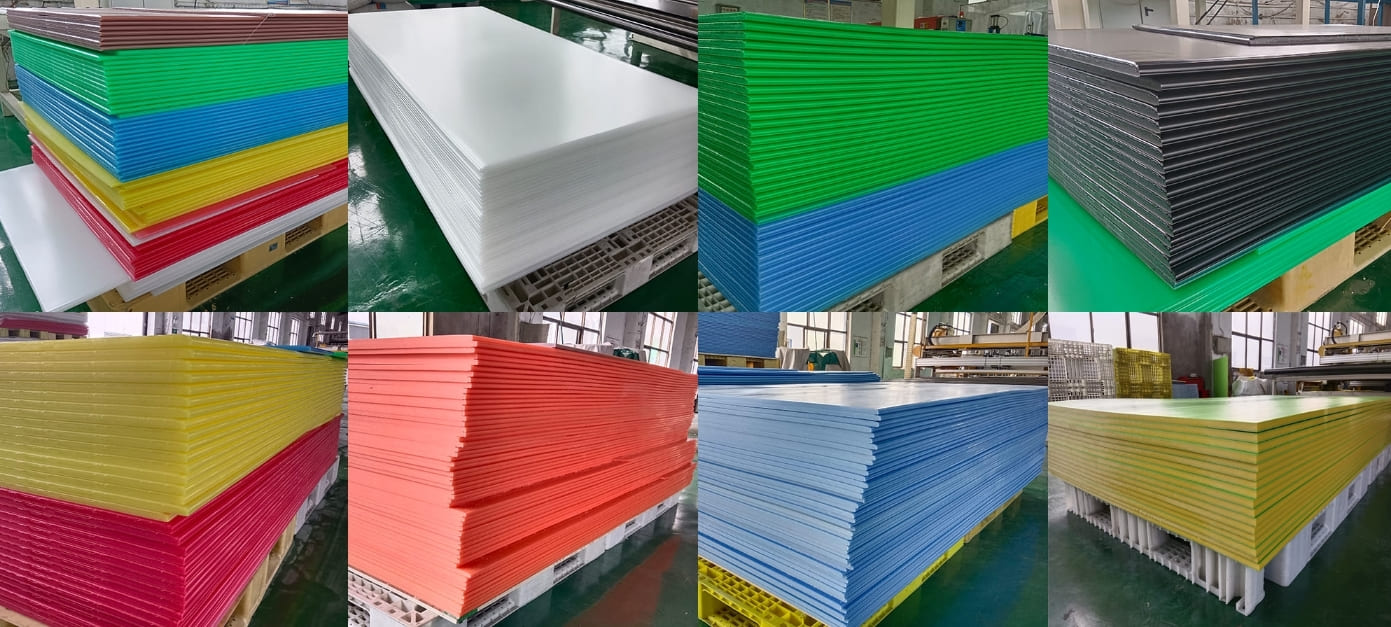

4. Classification by color specifications : more than just a visual system

- ● Natural color (milky white and translucent): retains the best mechanical properties.

- ● Black sheet: contains 2.5% carbon black, the first choice for UV resistance.

- ● Color series: red/blue/yellow, etc., colored with inorganic pigments.

5. Classification by density grade : from general materials to special HDPE sheets

- ● Low density type (0.935-0.945g/cm³): high toughness, suitable for cushioning materials.

- ● High density type (0.946-0.955g/cm³): balanced performance, accounting for 60% of the market share.

- ● Ultra-high density type (0.956-0.965g/cm³): ultra-high rigidity, used for heavy-load conditions.

Purchasing Guide : 3 Steps to Select the Best HDPE Sheet Type

- ● Step 1: Identify load conditions (dynamic/static, impact frequency).

- ● Step 2: Detect environmental factors (chemical corrosion, UV irradiation intensity).

- ● Step 3: Verify certification qualifications (FDA/CE/ROHS, etc.)

Through the in-depth analysis of the above five classification systems, I believe you have fully grasped the selection logic of HDPE sheet. For more information about HDPE sheet or Get free samples , please feel free to contact us.