First of all, we are engaged in construction and maintenance. Whether it is on a construction site or on a lawn, ground protection mats have become a necessary tool for us, because they not only allow our work equipment to pass through the ground smoothly, but also prevent the ground from being damaged by heavy equipment, especially on the lawn. So the question is, how do we choose ground protection mats?

Popular ground protection mats on the market

1. Metal ground protection mats

This ground protection mat is mainly made of aluminum alloy, stainless steel or carbon steel, and has the characteristics of high strength, wear resistance and corrosion resistance. Even in a humid environment, there is no need to worry about rusting. It can be used in various application environments, and its service life is up to 20 years or more. This long-lasting durability reduces the maintenance frequency and reduces the replacement cost. This ground protection mat is suitable for industrial areas, docks, parking lots and other places that need to bear heavy loads.

But the disadvantages are also obvious. The weight of this ground protection mat is relatively heavy. It is not convenient for construction workers in mobile locations to carry and lay it frequently, and it requires several people to work together or even use equipment to assist, and the initial procurement cost is relatively high.

2. Plastic ground protection mat

Plastic ground protection mat is generally made of high-density polyethylene (HDPE) material. It has the advantages of light weight, chemical corrosion resistance, and easy cleaning. It is the most commonly used anti-skid plate in construction.

This material’s ground protection mat is light in weight and low in price compared to metal. What’s more important is that this ground protection mat has very little damage to the ground on the lawn. The service life in a general working environment can reach about 7 years, and this material is recyclable and will not affect the environment. The high-grade pattern can maintain a good anti-slip effect even on rainy days.

A mat weighs about 39kg, and ordinary people can complete the laying work by themselves.

Disadvantages If it is often used in bad ground conditions, it may only have a lifespan of 3-5 years.

3. Rubber ground protection mat

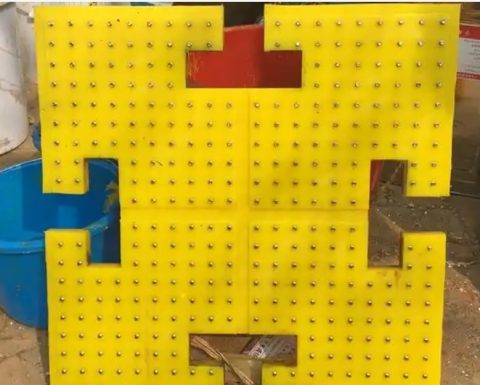

This type is a mixture of rubber and metal. Compared with the traditional single metal ground protection mat, it is more suitable for the working surface of the oil field drilling platform.

The principle is to die-cast steel nails with a diameter of 4mm in the rubber, where the rubber plate is 30mm thick, and the steel nails are exposed 5mm from the plate surface. The distance distribution between the steel nails is more reasonable. When the operator steps on it, there are always 30 steel nails protruding from the sole of the foot, which feels comfortable and plays an anti-skid role. There is a 2mm boss on the bottom of the rubber plate to prevent slipping on both sides.

How to choose ground protection mat

When we chose, we first considered the usage scenario. Our construction sites often change. Carrying these mats is first of all flexible and convenient. Metal ground protection mat are definitely not suitable. They are too heavy and not suitable for manual transportation (we don’t have equipment to carry them).

Secondly, our construction scenes are often on the lawn, and the lawn cannot be damaged. If we encounter long-term work, the lawn cannot be crushed.

Finally, combined with our budget, we chose a reusable natural HDPE ground protection mat. It weighs 39kg and can be carried by one person and it’s recycled . The convenience and efficiency of work are greatly improved.

The material is softer than metal, which reduces the damage to the contact surface with the lawn. In addition, the natural color can pass through the sun, and long-term use will not increase the damage to the lawn.